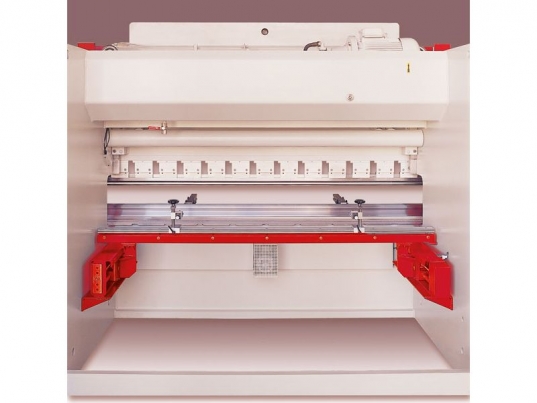

Morgan Rushworth PB NC 4100/160 Hydraulic Pressbrake

The conventional PB series pressbrake are manufactured with a heavy duty welded steel frame with strong tortion bar and hydro mechanical balancing system ensuring a long working life. PB machines range from 35 tonnes through to 300 tonnes with a bending length of up to 4100mm. All PB machines accept euro style tooling and are supplied with digital readouts for stroke control and for the power backgauge position. Side and rear guards with electrical interlocks are fitted as standard for increased safety.

Features

- European style top tool holders with wedge adjustment.

- Standard tooling: Gooseneck top tool and multi-vee bottom tool.

- Front operated, 750mm ballscrew backgauge with digital readout control (to 0.1mm precision) and two finger-stops with micro-adjustable height.

- Ram stroke control by precision mechanical-stops built into each cylinder and electrically adjusted by push-buttons with a digital position display.

- Independent position control of one cylinder-stop to provide fine angle adjustment and/or conical bending possibility.

- Pressure switch and gauge to regulate bending tonnage and to prevent overbending due to bottoming of tools.

- Pre-set, two-speed bending cycle giving fast approach, slow bending and fast return.

- 3-function footswitch: normal bending, beam pause at any stroke point, automatic beam return upon release of footswitch.

- Pendant control unit.

- Hand screw clamps and chains to align and secure bottom die.

- Two backgauge fingers.

- Two front support arms.

Options

- Programmable (NC) control for Y (stroke) and X (backgauge) axes.

- 1000mm backgauge length.

- Top tool quick release clamps.

- Laser tool guard.

- Anti deflection system.

- Additional backgauge fingers.

- Additional front support arm.

Capacities

Technical Specification

| MODEL | PB NC 4100/160 | ||

|---|---|---|---|

| Bending power tonnes | 160 | ||

| Bending length mm | 4100 | ||

| Distance between columns mm | 3550 | ||

| Y rapid speed mm/sec | 90 | ||

| Y working speed mm/sec | 8 | ||

| Y return speed mm/sec | 75 | ||

| Travel in X axis mm | 750 | ||

| Oil capacity Ltr | 260 | ||

| Motor power kW | 11 | ||

| Stroke mm | 140 | ||

| Daylight mm | 500 | ||

| Throat depth mm | 310 | ||

| Table height mm | 880 | ||

| Table width mm | 170 | ||

| Machine width mm | 1430 | ||

| Length mm | 5300 | ||

| Height mm | 2450 | ||

| Width mm | 1950 | ||

| Weight kg | 12500 | ||

Similar Models

| MODEL | PB NC 3700/240 | ||

|---|---|---|---|

| Bending power tonnes | 240 | ||

| Bending length mm | 3700 | ||

| Distance between columns mm | 3250 | ||

| Y rapid speed mm/sec | 70 | ||

| Y working speed mm/sec | 8 | ||

| Y return speed mm/sec | 55 | ||

| Travel in X axis mm | 750 | ||

| Oil capacity Ltr | 260 | ||

| Motor power kW | 18.5 | ||

| Stroke mm | 160 | ||

| Daylight mm | 565 | ||

| Throat depth mm | 310 | ||

| Table height mm | 880 | ||

| Table width mm | 240 | ||

| Machine width mm | 1650 | ||

| Length mm | 4950 | ||

| Height mm | 2650 | ||

| Width mm | 2250 | ||

| Weight kg | 14000 | ||

| MODEL | PB NC 4100/200 | ||

|---|---|---|---|

| Bending power tonnes | 200 | ||

| Bending length mm | 4100 | ||

| Distance between columns mm | 3550 | ||

| Y rapid speed mm/sec | 100 | ||

| Y working speed mm/sec | 8 | ||

| Y return speed mm/sec | 75 | ||

| Travel in X axis mm | 750 | ||

| Oil capacity Ltr | 260 | ||

| Motor power kW | 15 | ||

| Stroke mm | 150 | ||

| Daylight mm | 510 | ||

| Throat depth mm | 310 | ||

| Table height mm | 880 | ||

| Table width mm | 200 | ||

| Machine width mm | 1650 | ||

| Length mm | 5300 | ||

| Height mm | 2520 | ||

| Width mm | 2200 | ||

| Weight kg | 14500 | ||