Piranha P40 Hydraulic Steelworker

Piranha P40 Single Operator Steelworker gives metal fabricators outstanding quality and innovative features. Every Piranha provides quality work, saving time in set up, adaptability and versatility through a wide range of tooling, and factory engineering support.

Features

Punch Station

The urethane strippers keep the material flat to ensure a better quality punch. The shorter stroke ensures faster productivity and with no adjustments required results in an efficient and easy to use production.

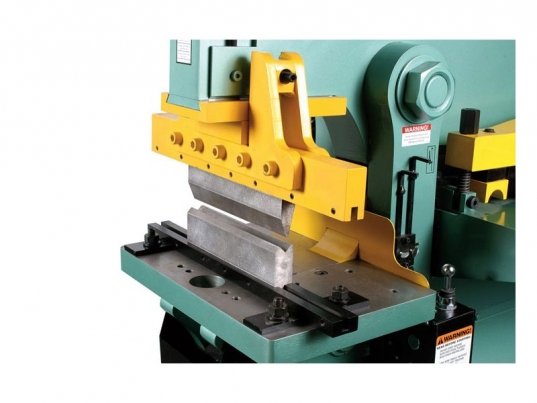

Shearing Station

The urethane hold-downs clamp and unclamp the material automatically with each stroke ensuring faster productivity. Unlike other conventional steelworkers the parts remain clamped during the entire shearing cycle to ensure a more accurate result. The complete clamping cycle promotes longer blade life making it much more cost effective.

Shearing Visibility

Much easier to line up a cut line to the shear blade as the operator has a direct line of sight.

Shear Blade

The low rake angle shear blade results in flatter parts being produced at a better quality. Piranha provide four shear edges on each blade to enhance cost efficiency and blade longevity.

Angle Shear

The floating upper blade seats in the centre of the angle eliminating distortion ensuring the cut piece does not deform.

Coper Notch

The low rake angle blade keeps the part flat and under control during notching process.

Bending Attachment

The open ended attachment allows the angle to bent easily.

Installing the Attachment

The dovetail slide makes the bending attachment easy to install.

Ease of Use

All attachments and stations are at the same height making it easier to use. No need to adjsut the feed table height between stations.

Options

- Pipe/Tube Bending Attachment

- Channel Die Block

- Bending Attachments – Optional sizes range from 300 – 1120mm

- 28XX Punch Attachment

- Press Brake Tooling Holders

- Quick set Gauging Tables – Fast set-up for punching multiple holes. Includes plate & angle-gauging guide bars. With left and right hand extensions available in 1.5m and 3m lengths.

- Channel Shear

- Bar Bender – Up to 65mm depending on available tonnage with adjustable die for different radii.

- Mechanical Backgauges

- Electrical Backgauges

- 38mm Oversize Punch Attachment

- Roller Feed Tables

Capacities

Technical Specification

| MODEL |

P40 |

||

|---|---|---|---|

| Throat Depth mm | 130 | ||

| Open height mm | 300 | ||

| Closed height mm | 190 | ||

| Stroke length mm | 101 | ||

| Plate table size (D-W) mm | 200 x 250 | ||

| Punch hole size (material) kN | 355 | ||

| Max hole size (material) mm | 25 - 38 | ||

| Plate shear mm | 330 Long, 150 x 150; 12 x 200; 6 x 330 | ||

| Angle shear mm | 90 x 90 x 8 | ||

| Bar shear round mm | 6 - 36 | ||

| Bar shear square mm | 12 - 25 | ||

| Copper kN | 350 | ||

| Notcher mm | 60 x 75 x 6 | ||

| Optional Bending attachment length mm | 150 - 300 | ||

| Punch end strokes mm/min | 50 / 12 | ||

| Work station height (approx) mm | 1067 | ||

| Fluid capacity ltr | 45 | ||

| Motor kW | 3 | ||

| Length mm | 610 | ||

| Width mm | 1397 | ||

| Height mm | 1473 | ||

| Weight kg | 771 | ||

Similar Models

| MODEL |

P70 |

||

|---|---|---|---|

| Throat Depth mm | 250 | ||

| Open height mm | 380 | ||

| Closed height mm | 260 | ||

| Stroke length mm | 123 | ||

| Plate table size (D-W) mm | 300 x 530 | ||

| Punch hole size (material) kN | 625 | ||

| Max hole size (material) mm | 30 - 114 | ||

| Plate shear mm | 460 Long, 25 x 150; 20 x 300; 12 x 460 | ||

| Angle shear mm | 127 x 127 x 13 | ||

| Bar shear round mm | 12 - 50 | ||

| Bar shear square mm | 12 - 35 | ||

| Copper kN | 670 | ||

| Notcher mm | 90 x 125 x 10 | ||

| Optional Bending attachment length mm | 300 - 600 | ||

| Punch end strokes mm/min | 40 / 19 | ||

| Work station height (approx) mm | 1067 | ||

| Fluid capacity ltr | 94 | ||

| Motor kW | 11 | ||

| Length mm | 787 | ||

| Width mm | 2007 | ||

| Height mm | 1626 | ||

| Weight kg | 1928 | ||

| MODEL |

P90 |

||

|---|---|---|---|

| Throat Depth mm | 300 | ||

| Open height mm | 400 | ||

| Closed height mm | 260 | ||

| Stroke length mm | 133 | ||

| Plate table size (D-W) mm | 370 x 530 | ||

| Punch hole size (material) kN | 800 | ||

| Max hole size (material) mm | 28 - 127 | ||

| Plate shear mm | 520 Long, 25 x 300; 20 x 450; 12 x 500 | ||

| Angle shear mm | 150 x 150 x 16 | ||

| Bar shear round mm | 12 - 50 | ||

| Bar shear square mm | 12 - 35 | ||

| Copper kN | 845 | ||

| Notcher mm | 100 x 150 x 10 | ||

| Optional Bending attachment length mm | 300 - 600 | ||

| Punch end strokes mm/min | 40 / 19 | ||

| Work station height (approx) mm | 1118 | ||

| Fluid capacity ltr | 94 | ||

| Motor kW | 11 | ||

| Length mm | 889 | ||

| Width mm | 2286 | ||

| Height mm | 1689 | ||

| Weight kg | 2812 | ||