Simasv T22 DIGIT 1 Axis CNC Hydraulic Horizontal Bending Press

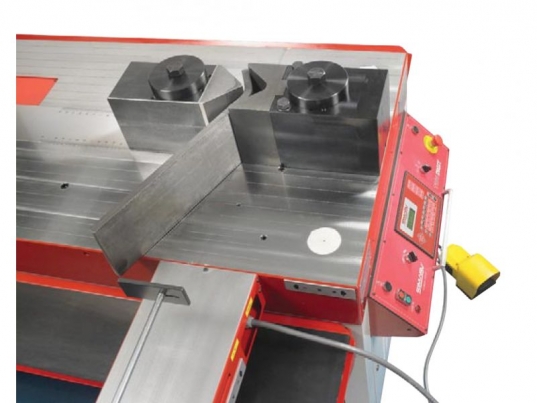

The Simasv CNC hydraulic horizontal bending machines are ideal for precision bending, straightening, punching and shearing. All models are equipped with powerful hydraulic cylinders located below the table providing an unencumbered working area. This is of particular benefit compared with traditional bending machines and pressbrakes as enclosed bends can be completed without colliding with the machine frame.

The programming of digitally controlled models is simple and functional and ensured via the electronic SlMplylogik type CN which, allows the operator to programme different work procedures without re-processing the piece

Available with capacities from 22 tonnes up to 100 tonnes and with a large range of tooling, these machines have proved capable of performing a whole variety of operations.

Features

- Very adaptable machine able to render many functions.

- Very quiet operation.

- Rapid change tool pins.

- Stroke regulation by means of extremely sensitive electric limit switches and graduated rule.

- Large range of special tooling.

- Ideal for jobbing or production applications

- Displaying on a high luminescence and resolution LCD screen of all working functions with 16x2 led characters

- Touch-screen keyboard, complete with 35 keys 16x2 led characters, full view of both axes "X" (axis stroke – punch) and "Y" (axis stroke side gauge positioner)

- Memory of 550 programs in "X" axis and "Y" axis, each of the 2 axis has a program with 15 different lines – that can be repeated 999 times

- BENDING FUNCTION: (with die + punch) programming in DEGREES of the bending angle directly from CN, data setting punch and die material thickness - possibility of setting and adjusting back elastic coefficient to every different angle

- TUBE BENDING FUNCTION: programming in DEGREES of the bending angle directly from the CN with the possibility of setting coefficient adjustment elastic-return

- 5 language options

- Measurement conversion millimetres / inches

- Programs selector: manual, semi-automatic, automatic

- Positioning accuracy: ± 0.1 mm

- Stroke speed adjustment via flow adjustment valve automatic control from CN

- USB port for downloading programs on an external memory stick for saving and/or input data (optional)

Options

Capacities

Technical Specification

| MODEL | T22 DIGIT 1 | ||

|---|---|---|---|

| Table size mm | 630 x 1100 | ||

| Max operating pressure ton | 22 | ||

| Carriage stroke mm | 200 | ||

| Max stroke of mobile punch mm | 200 | ||

| Mobile punch stroke adjustment | YES | ||

| Carriage speed mm/min | 1750 | ||

| Mobile punch advance and retrieval speed mm/min | 1980 | ||

| Mobile punch operating speed mm/min | 470 | ||

| Speed selection device | YES | ||

| Mobile & fixed pins - height mm | 120 | ||

| Mobile & fixed pins - diameter mm | 55 | ||

| Slide lubrication | Manual | ||

| Motor kW | 1.5 | ||

| Length mm | 1200 | ||

| Width mm | 900 | ||

| Height mm | 920 | ||

| Weight kg | 650 | ||

Similar Models

| MODEL | T22 DIGIT 2 | ||

|---|---|---|---|

| Table size mm | 630 x 1100 | ||

| Max operating pressure ton | 22 | ||

| Carriage stroke mm | 200 | ||

| Carriage speed mm/min | 1750 | ||

| Speed selection device | YES | ||

| Tool holding pins - height mm | 120 | ||

| Tool holding pins - diameter mm | 55 | ||

| Slide lubrication | Automatic | ||

| Motor kW | 1.5 | ||

| Length mm | 1100 | ||

| Width mm | 2450 | ||

| Height mm | 925 | ||

| Weight kg | 790 | ||